Optical Measurement | Light Measurement | Remote Sensing

HD-THERMASTER - Temperature control during sun protection testing

HD-THERMASTER

HD-THERMASTER – Temperature control during sun protection testing

The HD-THERMASTER has been specifically designed to control and ensure the temperature at the substrate surface all during the process of In Vitro sunscreen testing.

DESCRIPTION

First, totally adapted for PMMA Molded Helioplates HD6 and PMMA Sandblasted Helioplates SB6, these substrates have to be placed on the HD-THERMASTER (over the metallic support) at least 10 min before starting the test to ensure the surface temperature.

Second, the metallic support + the substrate is used to maintain the temperature by inertia during the weighing and spreading steps (< 2 min).

Finally, the substrate is replaced on the HD-THERMASTER in the dark to ensure the surface temperature control during the drying step.

RESULTS

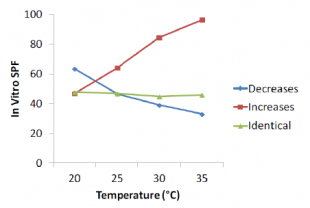

The temperature influence from 20°C to 35 °C has been studied on 37 sunscreen products (including: O/W emulsions, W/O emulsions, oils, sticks and sprays) coming from different

worldwide companies.

Results demonstrated that more than 80% of sunscreen products are thermo-sensitive during in vitro sunscreen testing with a product dependent behavior.